The sinking of the Titanic on the 15th of April, 1912 was one of the most news breaking and shocking events of the early 20th century. At the time of construction, the Titanic was the largest ship ever built, and used revolutionary design and technology to give it an unsinkable status. Many combining factors led to the magnitude of the disaster, including lack of lifeboats, flaws in the design of the ship and negligence of the crew. One factor that we can accurately evaluate with today’s technology is the quality of steel that was used for the Titanic, and if any shortcuts were taken during construction that may have contributed to the disastrous event. On top of this, could the quality of steel used to construct the Titanic have played a role in the disaster?

With today’s technology, we’re able to accurately evaluate the type of steel that was used for the Titanic, its quality, and if any shortcuts were taken during construction that may have contributed to its sinking.

According to a study conducted in 1998 and published in 2008 by Dr. Phil Leighly, a professor emeritus of metallurgical engineering at the University of Minnesota Rochester, the steel used for the Titanic did in fact play a role in the sinking of the Titanic. Using a recovered piece of steel from the ship’s hull and bulkhead that was larger than any others previously found, they were able to determine why the steel cracked on the hull.

The Titanic’s Steel Composition

After doing a series of impact tests based on their steel sample, Dr. Leighly’s team was able to determine that the steel used to build the ship was far inferior to modern steel. In fact, it was about 10 times more brittle in fact compared to the steel used to make today’s ships. Test results showed high concentrations of sulfur, oxygen, and phosphorus, and low concentrations of manganese, nitrogen and silicon. This was mainly a result of producing the steel using open-health furnaces. Pieces of steel from the hull have also appeared almost shattered, with no evidence of bending or deformation.

The Impact of Water Temperature on the Titanic’s Steel

The frigid waters in which the Titanic struck the iceberg most likely had a big impact on the time it took the Titanic to sink, which was about 2 hours and 40 minutes. The below freezing temperature water made the steel abnormally brittle and less impact resistant, contributing to the size of the ship’s hole and its rapid sinking. Passengers on the Titanic recalled hearing loud cracking noises coming from the ship’s structure while it was sinking. Dr. Leighly noted that you would expect groaning instead of cracking sounds when steel breaks, unless the steel is brittle.

The Design

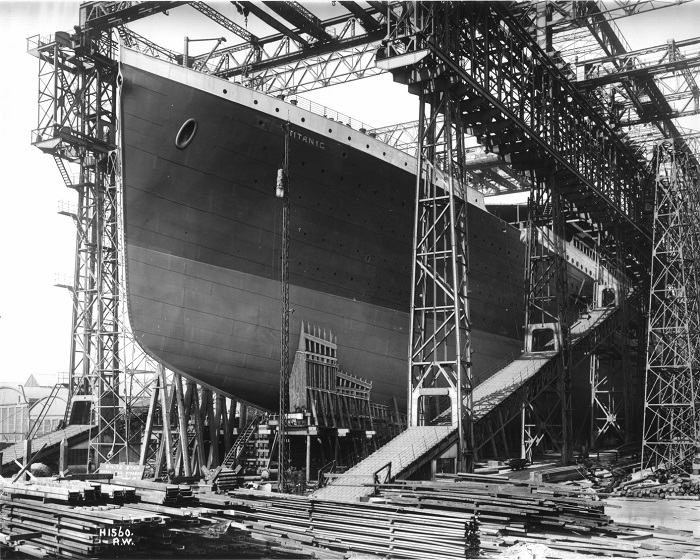

Because steel welding was still in its infancy during the Titanic’s construction, the colossal steel plate structure of the Titanic needed to be held together by over three million iron and steel rivets, which were hammered into place by hand. However, there were many additional flaws in the design of the ship that had little to do with the quality of the steel used, including compartments that were meant to be watertight, and lack of welding technology.

The steel used for the Titanic was far inferior to the steel typically used today, and was much more brittle and not nearly as impact resistant. However, it was certainly the best steel that could be produced at the time. Dr. Leighly concluded that flaws in the design of the ship were a much bigger factor of the sinking of the Titanic than the actual steel used in production.

What Can We Learn From Understanding the Steel of the Titanic?

While the steel of the Titanic was determined to have played a role in the ship’s sinking according to Leighly’s study, this was primarily due to the resources of the time period. Its brittle nature and lack of impact resistance contributed to the ship’s rapid sinking, but these are concerns today’s technology has remedied. Steel is significantly more durable than it was 100 years ago, meaning the steel composition of today’s ocean liners is very different from what was used in the Titanic’s construction.

For more facts and resources about steel, our resident experts at Capital Steel and Wire are here to answer your questions. If you’re seeking a solution for your own steel finishing needs, our vast product list is sure to have what you’re looking for.

Photo credit: